Terracotta -fashion embrace of nature in the city

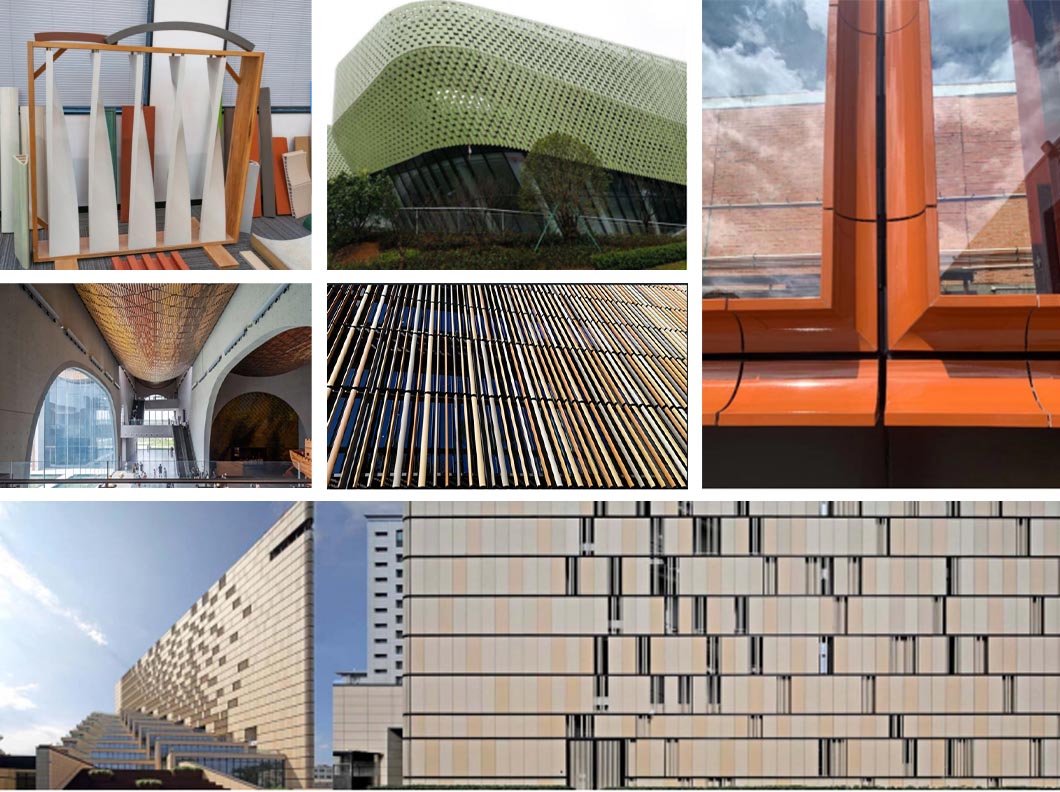

Civilization continues to push us toward urbanization. Our cities are getting bigger and denser. However, we all like highly developing cities, skyscrapers, and beautiful architecture, but everyone unconsciously seeks the natural genuine feeling from the surroundings.

Terracotta is baked natural clay, which is the most natural cladding material, that satisfies people's genetic affinity toward nature. People feel calm and secure when touched or surrounded by something natural. That is why more and more architects embrace terracotta as an ideal material for buildings.

For centuries, kiln-fired terracotta has been one of the most beautiful and long-lasting building materials that construction has known, Big-scale terracotta panels are relatively new to modern construction and architecture. Terracotta panel production technology was developed in Germany. It brought the availability of product design development and installation system improvement to the façade.

Material Characteristic

Togen’s terracotta panel is a product made of natural clay and contains no harmful substances. In the Environmental Product Declaration (EPD) its sustainability is assessed and verified.

Terracotta is an environmentally friendly and ideal material for building decoration since it’s non-radioactive, non-polluting, recyclable, has a low building load, and provides good thermal insulation and sound insulation. The material is durable with unfading color and has the properties of being resistant to weathering, erosion, external damage, and freeze and thaw. It complies Russian GOST requirement which is resistance to 100 cycles of freeze and thaw. Terracotta products are used in cold, hot, and humid regions of the world. Togen supplied terracotta products to Russia, Mongolia, the USA, South Korea, Singapore, Philippines, Malaysia, Australia, India, and Mauritius etc various climate countries.

Additionally, it is a safe material that is non-combustible and has great strength and strong thermal impact resistance. It’s allowed to be used above 100mm height.

Design flexibility

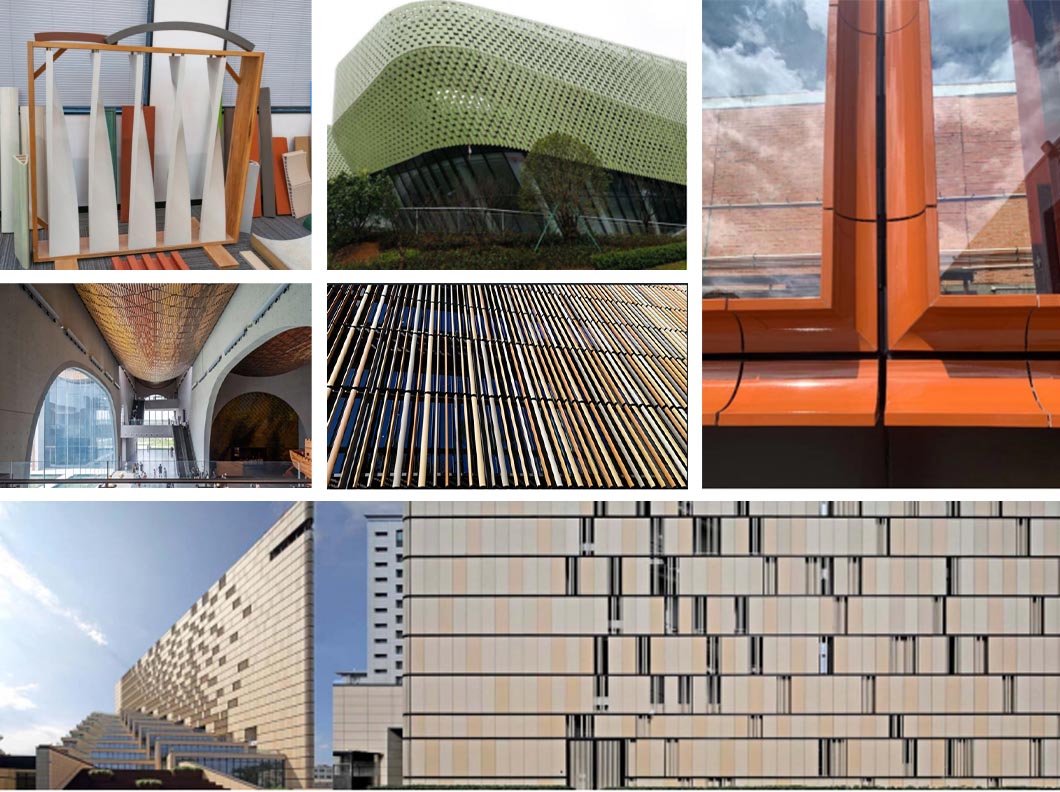

It is a naturally distinctive decoration element for both exterior and interior design due to the wide range of finishing and shape options. The Togen Terracotta Facade Products comprises terracotta facade panels, louvers, bricks, and customized profiles made from fired clay. The clay profiles are manufactured using different clay mixtures and obtain their surface characteristics and colors using specific firing cycles.

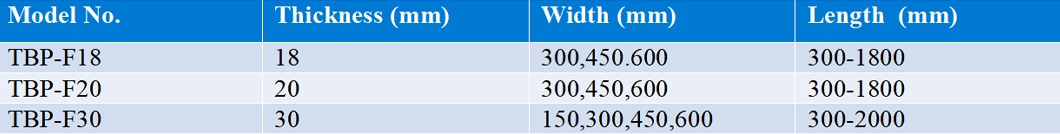

A. Size:

Terracotta panel size refers to thickness, width, and length.

We have standard thickness and width which has existing molds. Also available to customize our size within maximum limitation by creating new molds.

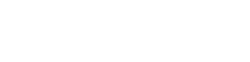

Standard size with existing molds:

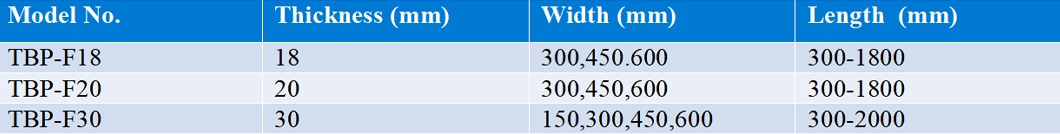

The economical size and maximum size for Terracotta Panel

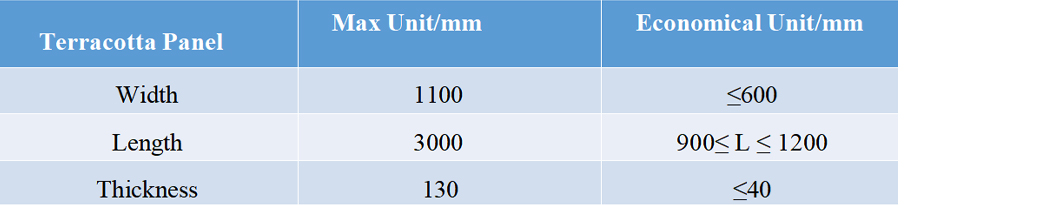

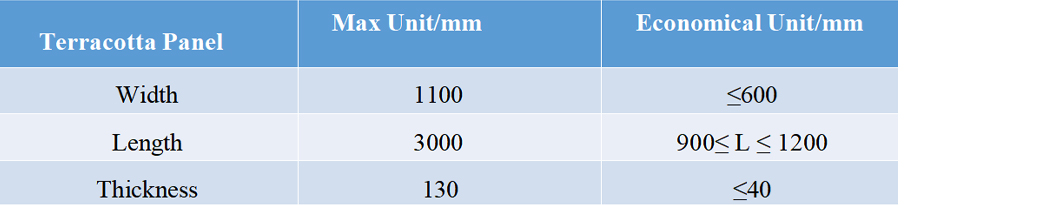

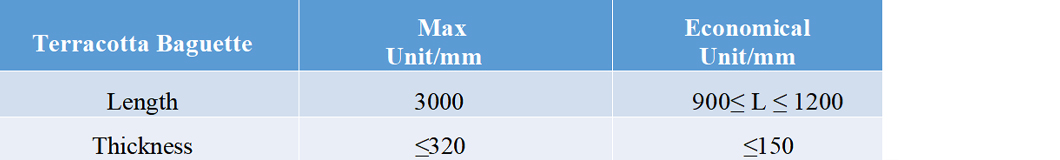

The economical size and maximum size for Terracotta Louver

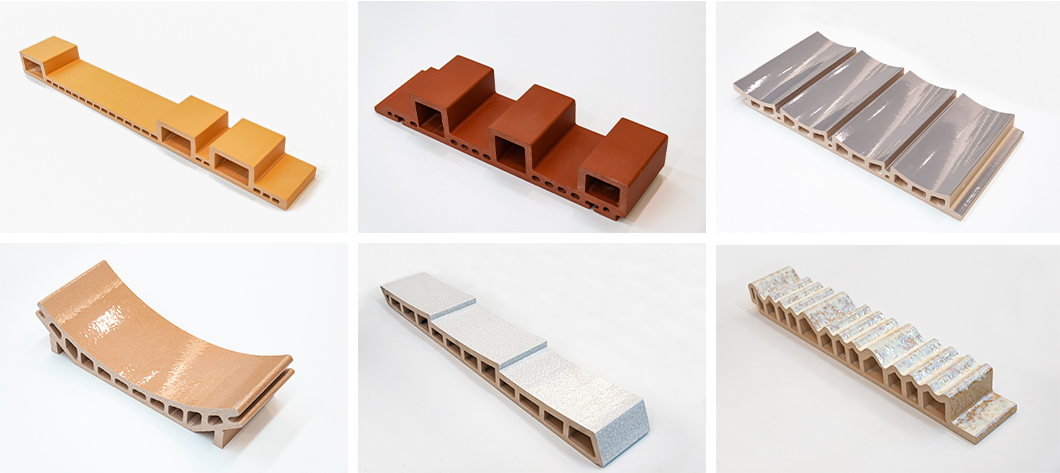

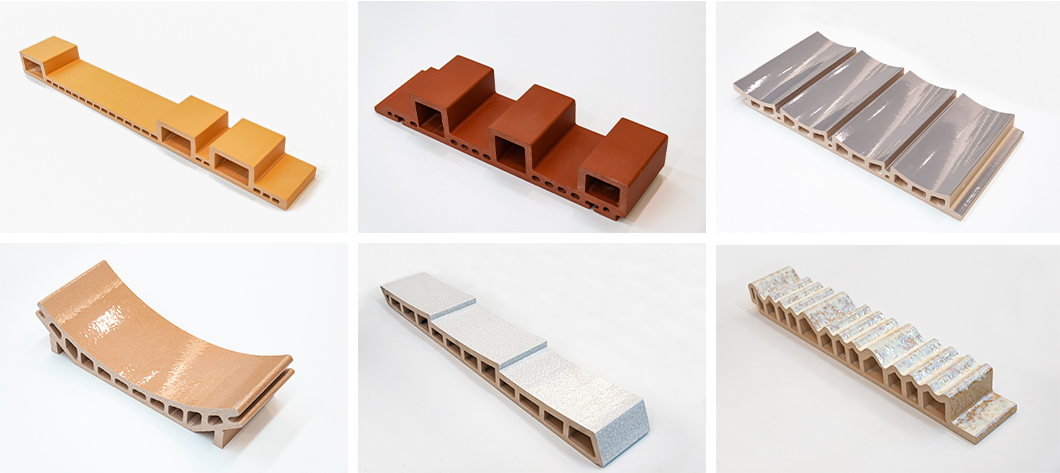

B. Shape:

We can customize products based on each project’s unique design. Our R&D team evaluates production feasibility and cost estimates based on the design intent of each project and makes our recommendations considering both technical and economic aspects.

For customized shape products we need to open a new mold to extrude it.

Togen is a specialist in irregular shape products and we are willing to develop new products with architects from the project's early design stage.

Types of panel and louver shapes: Flat, Groove. Concave, Convex, Panel and louver integrated shape, triangle, oval, elliptical, square, and other customized irregular shapes.

C. Surface finish and textures:

Terracotta panel has various surface finishes and can be customized limitless.

The surface finish also plays a big role in architecture’s expression.

Types of surface finishes are naturally smooth, rough, sandy, matt glazed, semi-matt glazed, glossy glazed, metallic glazed, strippy, dotted, brush, groove, etc

D. Color:

The white, yellow, red, grey, and brown series are the natural color series of terracotta clay. Through a special firing cycle and temperature adjustment, each series richen by limitless shades. Most of people imagine a terracotta façade with simple elegance warm natural tone.

But through glazing treatment terracotta panel achieves surprisingly various color selections. Glazed terracotta panels bring a limitless expression to the building's aesthetic.

We are able to simulate RAL, NSC, Pantone, etc international color codes, and actual samples of other materials as well. Good news! a free lab sample of customized color and surface treatment is available.

Application characteristic:

Products are fabricated in precise size at the factory. Corner panel miter cutting, hole drilling, groove opening, irregular shape cutting, etc all can be done at the factory. It saves a lot of time and labor at the construction site. It has a dry hanging open system which has great ventilation, and balance to the building. The fasteners are hidden. There are no outlet trace marks on the façade surface. It is easy to install and replace and almost maintenance-free due to its self-cleaning properties. Installing products in different directions or angles also brings unique features to the façade look.

Chinese were masters of clay products from ancient times. Best quality raw clay and inherited skilled clay masters are in China. We are offering terracotta products made of the best clay in China through the best technology imported from Europe. Willing to realize your unique design with our experienced skilled specialists team.

The use of Togen terracotta facades will lead to the creation of expressive buildings, which will meet the highest requirements concerning aesthetics, fire protection, durability, and workability.

Terracotta is baked natural clay, which is the most natural cladding material, that satisfies people's genetic affinity toward nature. People feel calm and secure when touched or surrounded by something natural. That is why more and more architects embrace terracotta as an ideal material for buildings.

For centuries, kiln-fired terracotta has been one of the most beautiful and long-lasting building materials that construction has known, Big-scale terracotta panels are relatively new to modern construction and architecture. Terracotta panel production technology was developed in Germany. It brought the availability of product design development and installation system improvement to the façade.

Material Characteristic

Togen’s terracotta panel is a product made of natural clay and contains no harmful substances. In the Environmental Product Declaration (EPD) its sustainability is assessed and verified.

Terracotta is an environmentally friendly and ideal material for building decoration since it’s non-radioactive, non-polluting, recyclable, has a low building load, and provides good thermal insulation and sound insulation. The material is durable with unfading color and has the properties of being resistant to weathering, erosion, external damage, and freeze and thaw. It complies Russian GOST requirement which is resistance to 100 cycles of freeze and thaw. Terracotta products are used in cold, hot, and humid regions of the world. Togen supplied terracotta products to Russia, Mongolia, the USA, South Korea, Singapore, Philippines, Malaysia, Australia, India, and Mauritius etc various climate countries.

Additionally, it is a safe material that is non-combustible and has great strength and strong thermal impact resistance. It’s allowed to be used above 100mm height.

Design flexibility

It is a naturally distinctive decoration element for both exterior and interior design due to the wide range of finishing and shape options. The Togen Terracotta Facade Products comprises terracotta facade panels, louvers, bricks, and customized profiles made from fired clay. The clay profiles are manufactured using different clay mixtures and obtain their surface characteristics and colors using specific firing cycles.

A. Size:

Terracotta panel size refers to thickness, width, and length.

We have standard thickness and width which has existing molds. Also available to customize our size within maximum limitation by creating new molds.

Standard size with existing molds:

The economical size and maximum size for Terracotta Panel

The economical size and maximum size for Terracotta Louver

B. Shape:

We can customize products based on each project’s unique design. Our R&D team evaluates production feasibility and cost estimates based on the design intent of each project and makes our recommendations considering both technical and economic aspects.

For customized shape products we need to open a new mold to extrude it.

Togen is a specialist in irregular shape products and we are willing to develop new products with architects from the project's early design stage.

Types of panel and louver shapes: Flat, Groove. Concave, Convex, Panel and louver integrated shape, triangle, oval, elliptical, square, and other customized irregular shapes.

C. Surface finish and textures:

Terracotta panel has various surface finishes and can be customized limitless.

The surface finish also plays a big role in architecture’s expression.

Types of surface finishes are naturally smooth, rough, sandy, matt glazed, semi-matt glazed, glossy glazed, metallic glazed, strippy, dotted, brush, groove, etc

D. Color:

The white, yellow, red, grey, and brown series are the natural color series of terracotta clay. Through a special firing cycle and temperature adjustment, each series richen by limitless shades. Most of people imagine a terracotta façade with simple elegance warm natural tone.

But through glazing treatment terracotta panel achieves surprisingly various color selections. Glazed terracotta panels bring a limitless expression to the building's aesthetic.

We are able to simulate RAL, NSC, Pantone, etc international color codes, and actual samples of other materials as well. Good news! a free lab sample of customized color and surface treatment is available.

Application characteristic:

Products are fabricated in precise size at the factory. Corner panel miter cutting, hole drilling, groove opening, irregular shape cutting, etc all can be done at the factory. It saves a lot of time and labor at the construction site. It has a dry hanging open system which has great ventilation, and balance to the building. The fasteners are hidden. There are no outlet trace marks on the façade surface. It is easy to install and replace and almost maintenance-free due to its self-cleaning properties. Installing products in different directions or angles also brings unique features to the façade look.

Chinese were masters of clay products from ancient times. Best quality raw clay and inherited skilled clay masters are in China. We are offering terracotta products made of the best clay in China through the best technology imported from Europe. Willing to realize your unique design with our experienced skilled specialists team.

The use of Togen terracotta facades will lead to the creation of expressive buildings, which will meet the highest requirements concerning aesthetics, fire protection, durability, and workability.