CATEGORIES

- Terracotta Cladding

- Ceramic Art

- Metal Cladding

- Casted Aluminum

- Performance Louver

- Architectural Glass

- Glass Fittings

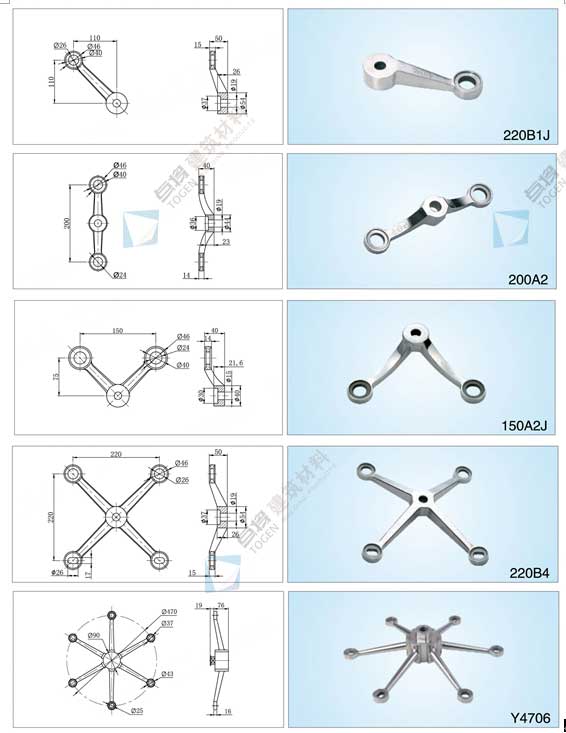

Point Fix Curtain Wall System

The spider keeps most of the glass exposed and takes up the least room. It is the clamps to support the glass to be the curtain wall. There are multiple choices of spider fittings with 1,2,3,4 or 6 arms.

| Item | performance |

| Arms | 1/2/4/6 |

| certification | GB/T20878-2007 |

| Surface | Satin / brushed finish or mirror / polished finish |

| Material | SS304 /SS316 |

| customization | Available |

| Size | 150mm,200mm,210mm,220mm,230mm,250mm,300mm etc. |

| Glass | Tempered/ Laminated/Insulated |

| Samples | Available |

| payment | T/T LC |

| Delivery time | 30-45 Days |

| MOQ | 50 piece |

Application

Why choose Togen:

1.Quality will be strictly-controlled during the process with certification of ISO9001

2. Customization is always available. If an item is not shown in our catalog, you can just send us a sample or email a photo and we will identify the item for you. That's where Togen can provide a valuable service to you.

3. We have over 10 years' experience on façade materials. Since 2005, we have been assisting customers with growing their businesses.

4. Samples are always available.

Quantity Assurance

.jpg)

Installation

.jpg) |

1. The front part of sider 2. Hexagon nu 3. Spring Washer 4. Eccentric Washer 5. Bespoke Nut 6. Spider 7. Bolt 8. Internal Threaded 9. Looking Ring 10. External Threaded Sleeve |

1. Welding the external threaded sleeve on the steel structure after taking off the internal threaded sleeve

2. Adjusting internal threaded sleeve to appropriate position, and then tighten up locking ring.

3. Putting bolt through the center hole of spider.

4. Adjusting installation position of spider, then compressing spider tightly with bolt.

5. Dismantling parts such as screw nut and so forth, making the front part of spider fixed on the glass.

6. Pre-adjusting hexagon nut, spring washer, offset washer to the required position for installation.

7. Eccentric washer to be placed on the spider and adjusted according to the requirement of installation, slot hole should be transverse when loading and should be vertical without loading, and the long hole faces down.

8. Putting the thread rod of routel through the hole of spider, and adjusting to appropriate position, then tightening bespoke nut.

9. Finally, sealing the surrounding between routel and glass with sealant to prevent from leaking water.

Tips to prevent stainless steel from rusting extremely:

1. Carrying out with solution treatment for the die and casting parts according to requirements.

2. Choosing the reasonable stainless steel mark according to the operating environment.

3. Selecting the proper surface treatment

4. Taking protective measures for hardware products into action on site.

5. Avoiding seeper and soot formation while design and application.

6. Keeping regularly cleaning.