CATEGORIES

- Terracotta Cladding

- Ceramic Art

- Metal Cladding

- Casted Aluminum

- Performance Louver

- Architectural Glass

- Glass Fittings

Low- E Glass

About Low- E Glass

Low-Emissivity glass is produced by magnetically enhanced sputtering of metal or metal compound coating under vacuum condition on different glass substrates, which is called as off-line Low-E or soft-coat Low-E.

Off-line Low-E is the best product solution to high energy saving performance facades or windows, because of Low-E coating's capability of spectral selection of desirable wave-length solar energy and heat. Low transmission of invisible infrared of solar energy (with wave-length above 780nm) and desirable visible light transmission to create low shading coefficient while desirable glass color and natural light indoor; Low

Emissivity of long wave length far infrared to create low U-Value. Off-line Low-E must be glazed into IGUs.

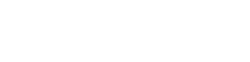

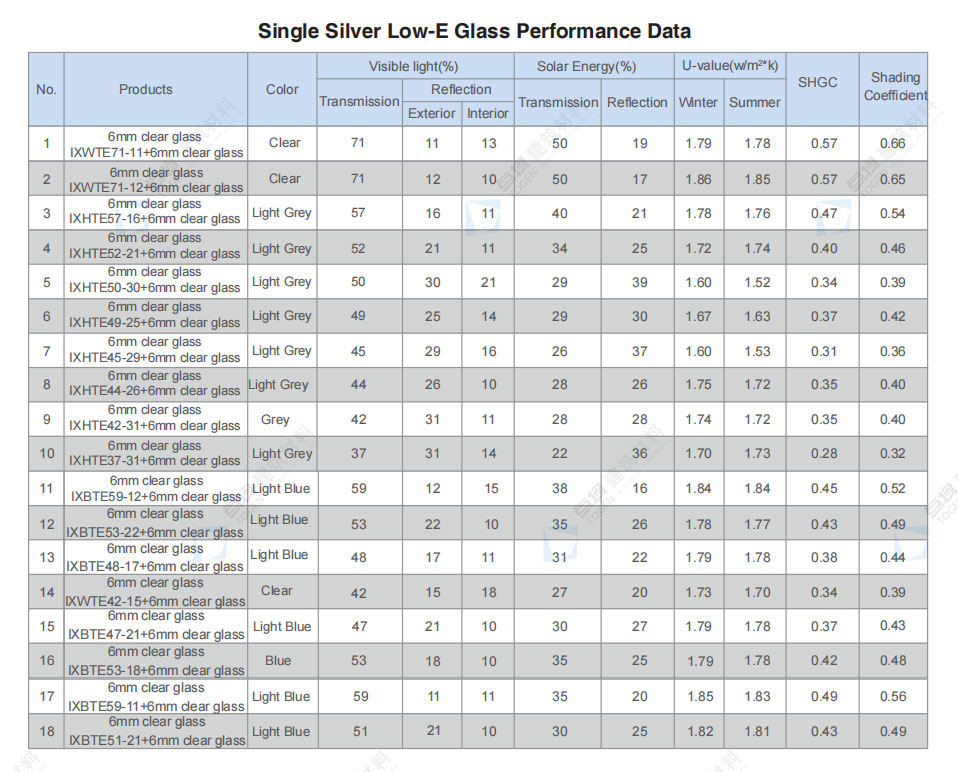

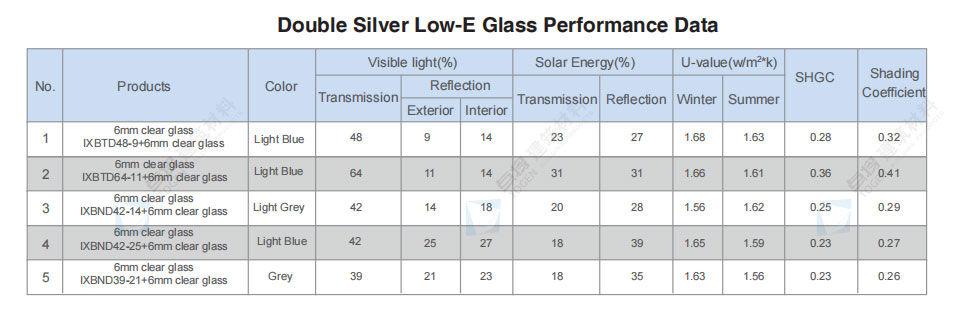

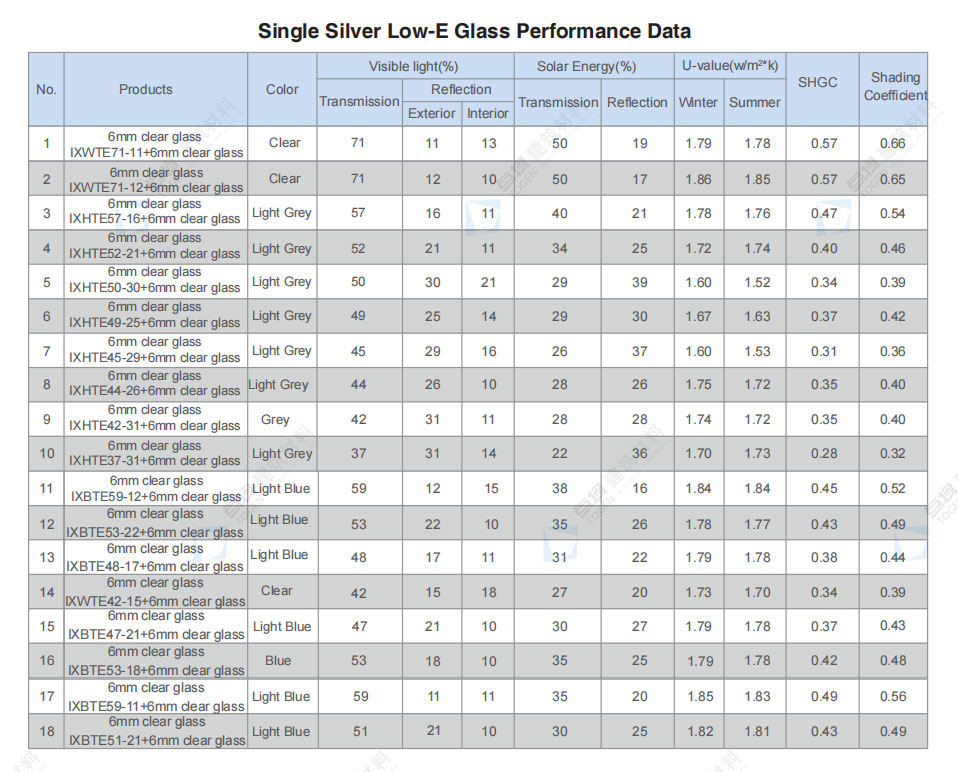

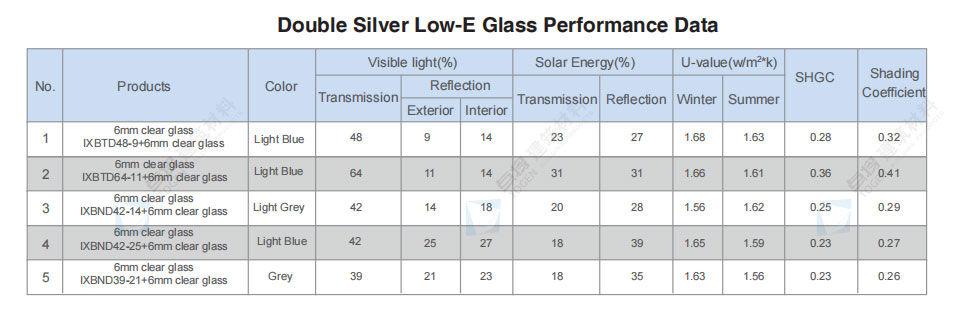

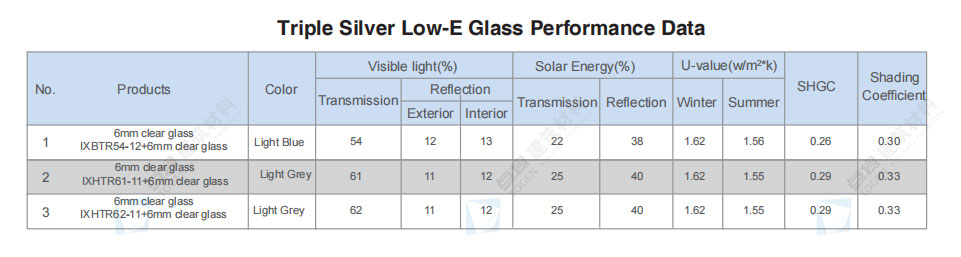

Low-E Glass Performance Data

The Comparision of AC Cost Saving Between Togen Double Silver Low-E Glass and Normal Glass

Remarks:

1. Simulation carried out under the following conditions, without considering the direction of building and sunlight.

2. Winter: Outside: -1℃ ,inside: 22℃ ,winter heating time:140 days (Not Considering daylight hours)

3. Summer: Outside: 32℃ ,Insider: 24℃ ; Sun Direct Radiation Time: 7 hrs/day

4. Summer Cooling Time: 100 days; Air Conditioner Operation Time:12 hrs/day

5. Building Area 24000m ,Glass Area 8000m ;

6. Commercial electricity cost:1RMB/KWH

Coating Line

1.Brand name: VAAT, imported Germany

2.Located in the same premise of other processing lines

3.Max size: 2540*7000mm

4.Auto loading & unloading machines

5.Auto protection film application machines

6.The best glass washer – Bentler, Germany

7.Dedicated water treatment center

8.On-line performance quality inspectors

9.Quality standard: ASTM C1376 BS/EN1096

Project reference

Low-Emissivity glass is produced by magnetically enhanced sputtering of metal or metal compound coating under vacuum condition on different glass substrates, which is called as off-line Low-E or soft-coat Low-E.

Off-line Low-E is the best product solution to high energy saving performance facades or windows, because of Low-E coating's capability of spectral selection of desirable wave-length solar energy and heat. Low transmission of invisible infrared of solar energy (with wave-length above 780nm) and desirable visible light transmission to create low shading coefficient while desirable glass color and natural light indoor; Low

Emissivity of long wave length far infrared to create low U-Value. Off-line Low-E must be glazed into IGUs.

Low-E Glass Performance Data

The Comparision of AC Cost Saving Between Togen Double Silver Low-E Glass and Normal Glass

Remarks:

1. Simulation carried out under the following conditions, without considering the direction of building and sunlight.

2. Winter: Outside: -1℃ ,inside: 22℃ ,winter heating time:140 days (Not Considering daylight hours)

3. Summer: Outside: 32℃ ,Insider: 24℃ ; Sun Direct Radiation Time: 7 hrs/day

4. Summer Cooling Time: 100 days; Air Conditioner Operation Time:12 hrs/day

5. Building Area 24000m ,Glass Area 8000m ;

6. Commercial electricity cost:1RMB/KWH

Coating Line

1.Brand name: VAAT, imported Germany

2.Located in the same premise of other processing lines

3.Max size: 2540*7000mm

4.Auto loading & unloading machines

5.Auto protection film application machines

6.The best glass washer – Bentler, Germany

7.Dedicated water treatment center

8.On-line performance quality inspectors

9.Quality standard: ASTM C1376 BS/EN1096

Project reference