Irregular Panel

Introduction to irregular aluminum panel

Irregular Aluminum Cladding Panels are aluminum veneer products that are processed according to the design requirements of the project, using precision processing equipment, through the processes of material cutting, leveling, hemming, slotting, punching, welding, grinding, and spraying.

3D aluminum panel are suitable for all kinds of interior and exterior walls, lobby facades, pillars, elevator edging, balcony packaging, advertising signs, indoor shaped ceilings and so on.

3D decorative wall panels are uniquely designed, structured and shaped. Combining the use of modern decoration with the design effect of the times, the essence of the irregular shape of the aluminum veneer is fully reflected.

Advantages of Aluminum Solid Panel

(1) Aluminum Solid Panel is boasted with light weight, high strength, and good rigidity. The weight of an aluminum panel of 3.0mm thickness is 8kg/sq meter, with flexural strength of 100-280 N/mm2.

(2) Good weather and corrosion resistance. Non-faded color guarantee for up to 25 years with the application of PVDF paint based on kynar-500 and hylur-500.

(3) Good processing technique. The panel is processed before spraying paint on the surface, and can be processed into a variety of complicated geometrical shapes.

(4) Even coating and vivid colors. The advanced electrostatic spraying technique enable paints to be sprayed evenly and attached closely to the panel. The rich assortment of colors also provides more choices for customers.

(5) Stainless and easy to maintain. Contaminants is not adhesive to PVDF coating, making the panel self-clean to a certain degree.

(6) Easy to install. There is no job site work required as the panel is ready-made in the factory. All it takes for installation is to fix the panels in the framework.

(7) 100% recyclable. Unlike glass, stone, and many other decorative materials, aluminum panel can be recycled at about 85%~90% the price of aluminum ingot.

Surface treatment

Our aluminum sheet surface treatment includes powder coating, PVDF powder coating, PVDF rolling coating, and wooden transfer. We ensure you the quality of our aluminum panel as we never used aluminum scrap or recycled aluminum.

Polyvinylidene fluoride (PVDF) coatings are a factory-applied, resin-based coating system, typically with embedded color pigment particles that support a wide range of matte-finish colors. They are most commonly used for architectural coating applications due to their superior resistance to weathering by sunlight, moisture, or temperature.

Aluminum wall cladding, curtain wall, and roofing sheet are some of the most common applications for PVDF coatings.

Polyester powder coating is a dry material sprayed onto a work piece and then cured to form a protective covering. This method of covering and protecting objects has a number of advantages over conventional wet coverings. Polyester powder coating creates a stronger and more durable finish and is more economical and safer for the environment than many forms of liquid coatings. As a result, powder coating systems have become very common in commercial and industrial processes

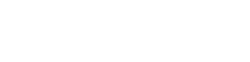

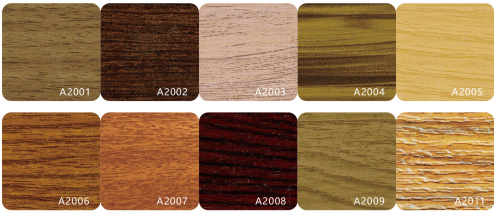

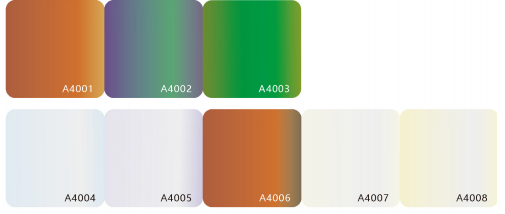

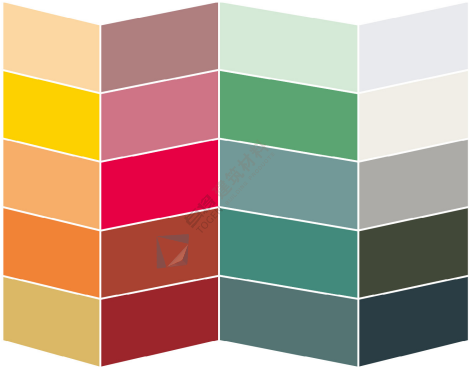

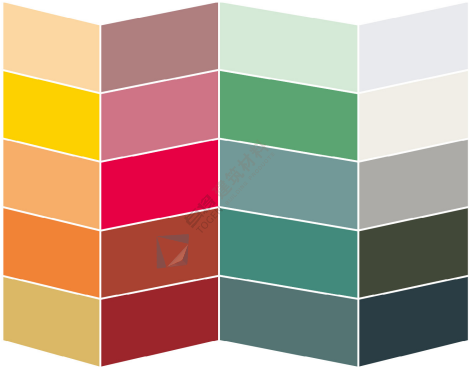

Pattern & Color

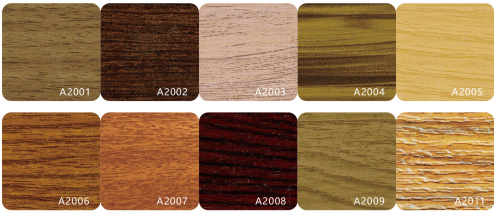

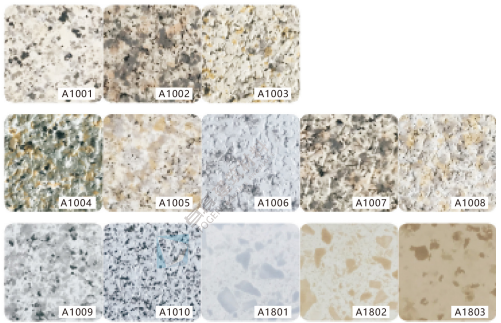

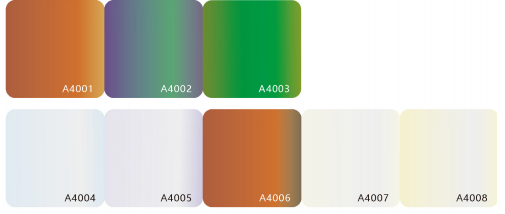

We supply wood finish, stone finish, Chameleon color, solid color, metallic color, and customized colors and patterns. Also if you have any other customized color please let us know your pantone/RAL color code, or send us your actual sample for us to simulate. Brief introduction to different colors and finishes:

Woodgrain Finish: Woodgrain Finish reminds people of ecology and environmental protection, reflecting simple but profound connotations.

Stone Finish: Stone finish can be defined as a new fashion universally used in office buildings and museums as it is serious and solemn. As a combination of tradition and modern, stone finish shows the development of ages

Chameleon color: Different colors keep transitioning in the sun, refreshing people's visual experience.

Metallic color: Metallic texture gives off a feeling of high-tech, which is stunning and mysterious, making people want to reach down the surface and touch

Solid Color:Solid color is a good choice as they are simple but straightforward and never seem to be out of date. Every single color can be an expression of the emotion architect is trying to convey

Custom finish: We provide Custom Finish tailored to your preferences. You name it, and we will do our best to guarantee your satisfaction.

Project

Irregular Aluminum Cladding Panels are aluminum veneer products that are processed according to the design requirements of the project, using precision processing equipment, through the processes of material cutting, leveling, hemming, slotting, punching, welding, grinding, and spraying.

3D aluminum panel are suitable for all kinds of interior and exterior walls, lobby facades, pillars, elevator edging, balcony packaging, advertising signs, indoor shaped ceilings and so on.

3D decorative wall panels are uniquely designed, structured and shaped. Combining the use of modern decoration with the design effect of the times, the essence of the irregular shape of the aluminum veneer is fully reflected.

Advantages of Aluminum Solid Panel

(1) Aluminum Solid Panel is boasted with light weight, high strength, and good rigidity. The weight of an aluminum panel of 3.0mm thickness is 8kg/sq meter, with flexural strength of 100-280 N/mm2.

(2) Good weather and corrosion resistance. Non-faded color guarantee for up to 25 years with the application of PVDF paint based on kynar-500 and hylur-500.

(3) Good processing technique. The panel is processed before spraying paint on the surface, and can be processed into a variety of complicated geometrical shapes.

(4) Even coating and vivid colors. The advanced electrostatic spraying technique enable paints to be sprayed evenly and attached closely to the panel. The rich assortment of colors also provides more choices for customers.

(5) Stainless and easy to maintain. Contaminants is not adhesive to PVDF coating, making the panel self-clean to a certain degree.

(6) Easy to install. There is no job site work required as the panel is ready-made in the factory. All it takes for installation is to fix the panels in the framework.

(7) 100% recyclable. Unlike glass, stone, and many other decorative materials, aluminum panel can be recycled at about 85%~90% the price of aluminum ingot.

Surface treatment

Our aluminum sheet surface treatment includes powder coating, PVDF powder coating, PVDF rolling coating, and wooden transfer. We ensure you the quality of our aluminum panel as we never used aluminum scrap or recycled aluminum.

Polyvinylidene fluoride (PVDF) coatings are a factory-applied, resin-based coating system, typically with embedded color pigment particles that support a wide range of matte-finish colors. They are most commonly used for architectural coating applications due to their superior resistance to weathering by sunlight, moisture, or temperature.

Aluminum wall cladding, curtain wall, and roofing sheet are some of the most common applications for PVDF coatings.

Polyester powder coating is a dry material sprayed onto a work piece and then cured to form a protective covering. This method of covering and protecting objects has a number of advantages over conventional wet coverings. Polyester powder coating creates a stronger and more durable finish and is more economical and safer for the environment than many forms of liquid coatings. As a result, powder coating systems have become very common in commercial and industrial processes

Pattern & Color

We supply wood finish, stone finish, Chameleon color, solid color, metallic color, and customized colors and patterns. Also if you have any other customized color please let us know your pantone/RAL color code, or send us your actual sample for us to simulate. Brief introduction to different colors and finishes:

Woodgrain Finish: Woodgrain Finish reminds people of ecology and environmental protection, reflecting simple but profound connotations.

Stone Finish: Stone finish can be defined as a new fashion universally used in office buildings and museums as it is serious and solemn. As a combination of tradition and modern, stone finish shows the development of ages

Chameleon color: Different colors keep transitioning in the sun, refreshing people's visual experience.

Metallic color: Metallic texture gives off a feeling of high-tech, which is stunning and mysterious, making people want to reach down the surface and touch

Solid Color:Solid color is a good choice as they are simple but straightforward and never seem to be out of date. Every single color can be an expression of the emotion architect is trying to convey

Custom finish: We provide Custom Finish tailored to your preferences. You name it, and we will do our best to guarantee your satisfaction.

Project