CATEGORIES

- Terracotta Cladding

- Ceramic Art

- Metal Cladding

- Casted Aluminum

- Performance Louver

- Architectural Glass

- Glass Fittings

Aluminum Perforated Panel

Introduction to perforated panel

Perforated metal panel, also known as perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched using CNC technology or in some cases laser cutting to create different holes sizes, shapes and patterns. Common equipment used for the perforation of metal include rotary pinned perforation rollers, die and punch presses, and laser perforations.

Surface treatment

Aluminum Solid Panel has been the building material commonly used in façade wall system. However, with the popularization of Perforation Aluminum Façade Wall, more and more customers tend to choose Aluminum perforated Panel as the decorative material of both the interior and exterior walls. With high quality and being environmental-friendly, Aluminum perforated Panel can be treated with different ways to present different finishes, thus forming façade walls of different styles.

Aluminum perforated Panel can be categorized into the following 3 kinds according to the surface treatment:

(1) Powder Coating Aluminum perforated Panel, which is mainly used in interior ceiling and wall, is lower in price but shall be protected from sunlight and rainwater.

(2) PVDF Coating Aluminum Perforated Panel is with good weather, UV, as well as acid & alkali resistance. The color is vivid and non-faded with a wide variety of choices. As a result, it is perfectly suitable to be used in both interior and exterior environment.

2 Ways to Perforate

1. CNC Punching Machine: CNC Punching Machine is a common machine for perforation, which is able to perforate rapidly in a large area.

2. Laser Beam: Laser Beam Perforation is a newly-developed technique. More expensive and sophisticated, this technique is conducted with higher precision and flexibility.

Advantages of Aluminum Perforation Panel

1. Aluminum Perforation Panel comes with a wide variety of hole patterns for selection. Different visual impact can be achieved with the combination of the panels in different hole patterns. Customization is available for architects to realize different building styles.

2. Aluminum Perforation Panel lets in light through its holes but leave enough privacy to people inside with the joint effect of lights and holes.

3. Aluminum Perforation Panel insulates sound. When installed in the ceiling, they can also prevent the arising of echo.

4. Aluminum Perforation Panel possesses great strength and durability. Compared to Aluminum Solid Panel of the same size, Aluminum Perforation Panel is relatively light.

5. Aluminum Perforation Panel is capable of controlling illumination and ventilation of the buildings. Its holes not only let in sunlight without direct solar radiation, but perform well in ventilation as wind is also let in and out. As a result, energy is saved, so is the maintenance cost.

6. Aluminum Perforation Panel is 100% recyclable. As it takes less metal to make Aluminum Perforation Panel, about 10%-40% less than what it needs to make a solid panel, it is lighter and thus reduces energy consumption during transportation.

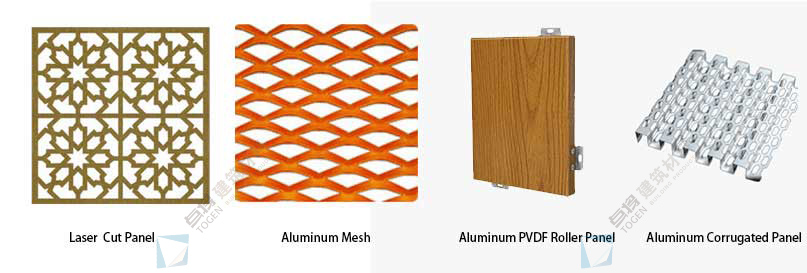

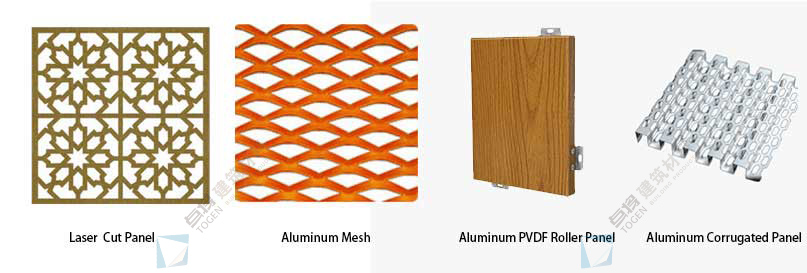

Related Products

Project

Perforated metal panel, also known as perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched using CNC technology or in some cases laser cutting to create different holes sizes, shapes and patterns. Common equipment used for the perforation of metal include rotary pinned perforation rollers, die and punch presses, and laser perforations.

Surface treatment

Aluminum Solid Panel has been the building material commonly used in façade wall system. However, with the popularization of Perforation Aluminum Façade Wall, more and more customers tend to choose Aluminum perforated Panel as the decorative material of both the interior and exterior walls. With high quality and being environmental-friendly, Aluminum perforated Panel can be treated with different ways to present different finishes, thus forming façade walls of different styles.

Aluminum perforated Panel can be categorized into the following 3 kinds according to the surface treatment:

(1) Powder Coating Aluminum perforated Panel, which is mainly used in interior ceiling and wall, is lower in price but shall be protected from sunlight and rainwater.

(2) PVDF Coating Aluminum Perforated Panel is with good weather, UV, as well as acid & alkali resistance. The color is vivid and non-faded with a wide variety of choices. As a result, it is perfectly suitable to be used in both interior and exterior environment.

2 Ways to Perforate

1. CNC Punching Machine: CNC Punching Machine is a common machine for perforation, which is able to perforate rapidly in a large area.

2. Laser Beam: Laser Beam Perforation is a newly-developed technique. More expensive and sophisticated, this technique is conducted with higher precision and flexibility.

Advantages of Aluminum Perforation Panel

1. Aluminum Perforation Panel comes with a wide variety of hole patterns for selection. Different visual impact can be achieved with the combination of the panels in different hole patterns. Customization is available for architects to realize different building styles.

2. Aluminum Perforation Panel lets in light through its holes but leave enough privacy to people inside with the joint effect of lights and holes.

3. Aluminum Perforation Panel insulates sound. When installed in the ceiling, they can also prevent the arising of echo.

4. Aluminum Perforation Panel possesses great strength and durability. Compared to Aluminum Solid Panel of the same size, Aluminum Perforation Panel is relatively light.

5. Aluminum Perforation Panel is capable of controlling illumination and ventilation of the buildings. Its holes not only let in sunlight without direct solar radiation, but perform well in ventilation as wind is also let in and out. As a result, energy is saved, so is the maintenance cost.

6. Aluminum Perforation Panel is 100% recyclable. As it takes less metal to make Aluminum Perforation Panel, about 10%-40% less than what it needs to make a solid panel, it is lighter and thus reduces energy consumption during transportation.

Related Products

Project