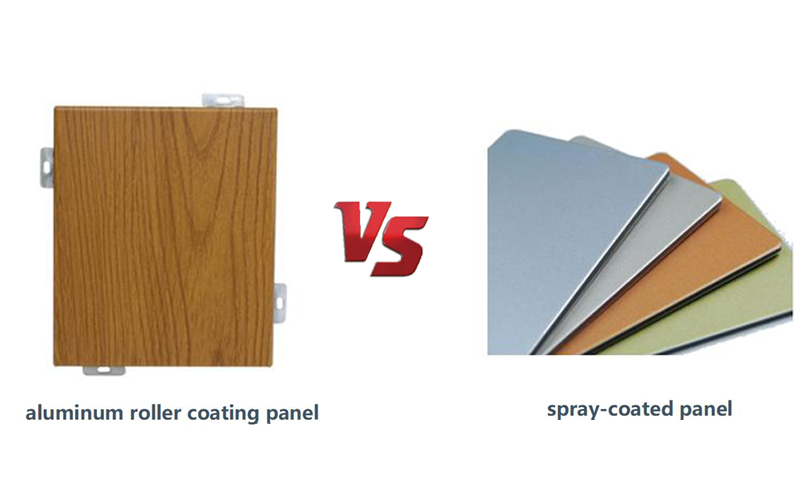

Are you still using aluminum spray coating panels? Aluminum Roller Coating technology can greatly satisfy your various and complex pattern requirements and make them all come into reality. Let’s have a look at the abundant advantages of the finished products.

1.Excellent Flatness: Compared with spray-coated panels, aluminum roller coating panels would have better panel flatness and less distortion. The aluminum internal stress has been fully relieved during pre-coating by high-temperature baking when it is still flat, it is fabricated without being welded and unlike spray-coated panel, once fabricated the roller coating panel won't be baked again.

2.Environment friendly: Unlike spray coating, roller coating does not create paint mist. And compared with 50% paint usage by spray coating, roller coating's paint usage is over 95%.

3.Excellent Color Consistency: Least coating thickness tolerance, least baking temperature tolerance and continuous coating on coil contribute to the excellent color consistency of roller coating aluminum panels.

4.Exquisite finish: The roller coating aluminum panel is pre-coated by way of pressing printing with non-granular, non-porous, stainless fine and smooth finish.

5.Various Patterns Available: Like roller printing technology, the roller coating aluminum panels are available with various vivid patterns including stone, timber, etc. by using different rollers engraved with different patterns.

6.High Efficiency: With automatic production line, the production efficiency is 20-100+ meters per minute, which ensures the faster delivery time.

7.Large size capacity: the maximum height of aluminum cladding panel with Pre-coated PVDF Roller Coating is 9 meters.